Die and Mold Industry

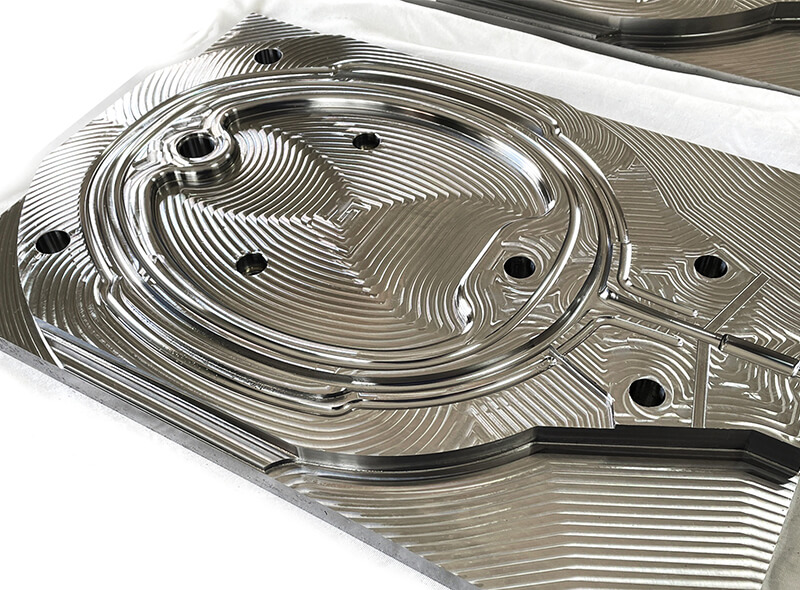

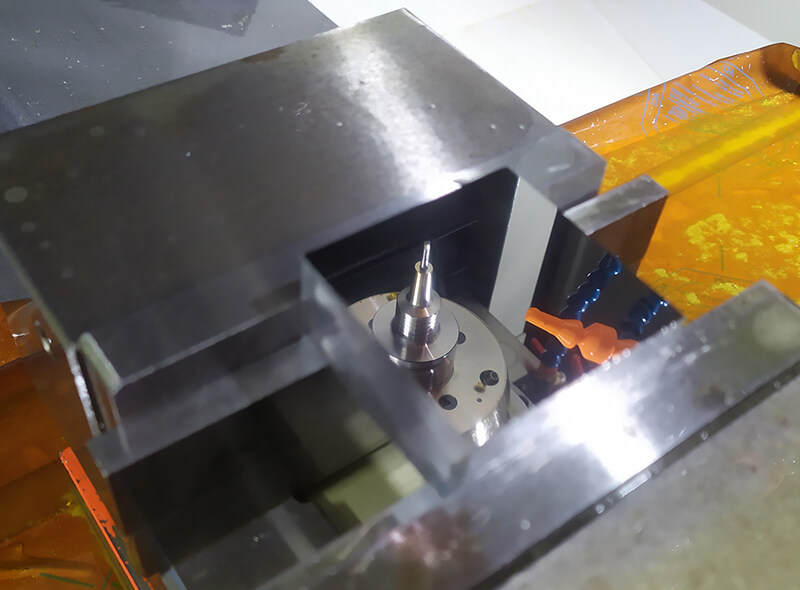

The GENTIGER machines with high-speed, highly rigid structures, and excellent thermal displacement suppression functions, in the processing of high-precision molds, such as optical molds, plastic molds, etc.

The surface effect is good, the precision of mold clamping is in place at one time, and the deep groove and angle can be accurately completed, reducing the timeliness of electrode processing discharge, reducing costs and improving efficiency. GENTIGER is the best choice for the mold industry.

According to the customer feedback, the machining accuracy can reach within ±0.005mm.

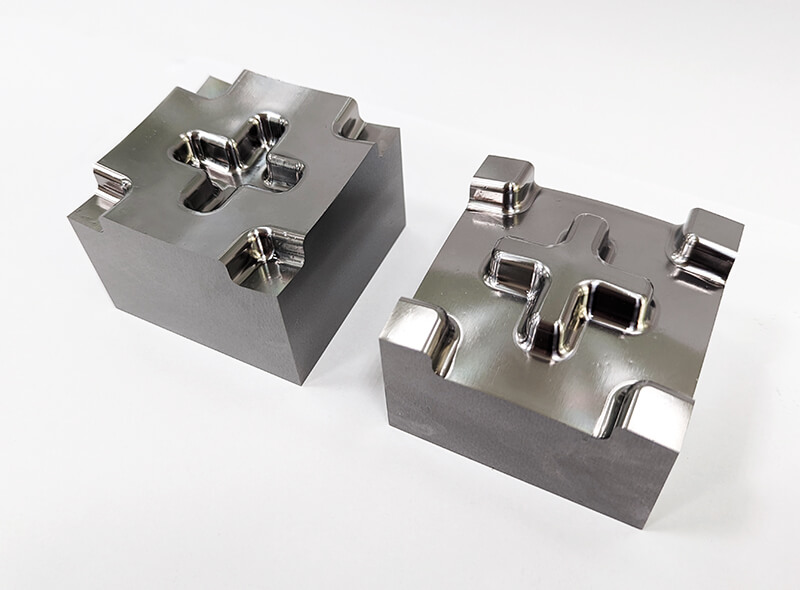

Plastic Mold

Work-piece:Tennis Racket Mold

Tennis Racket Mold

- Material:S54C

- Spindle Speed:14000 rpm

- Recommend:GT-86V

Positioning hole within 0.01mm

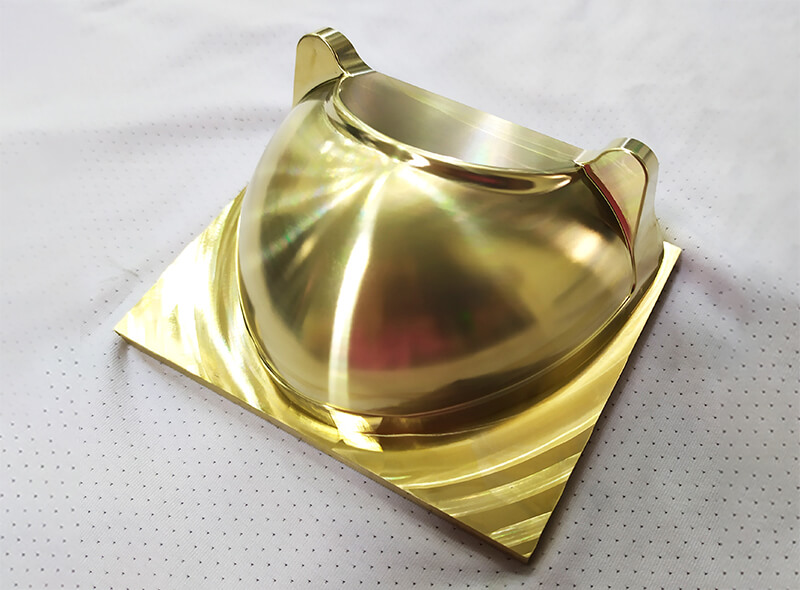

Copper Parts Processing

Mirror Cutting

Work-piece:Slope Surface cutting

Ra:0.16um