Application for Five-Axis Machining

Multi-axis CNC machining is applied to the cutting of complex and multi-faceted workpieces. It is suitable for machining precision parts or molds with various angles and negative angles, and is suitable for products in various industries.

According to the customer's needs, various simultaneous and fixed-angle processing of different swing angles is carried out. With the controller RTCP function, the processing accuracy can be more accurately grasped, and the processing efficiency of the co-moving axis can reduce errors and improve product timeliness; and it is equipped with high-precision CAM paths and the simulation syste, you can quickly, safely and reliably operate it.

GENTIGER five-axis high-speed machining center is your most reliable choice.

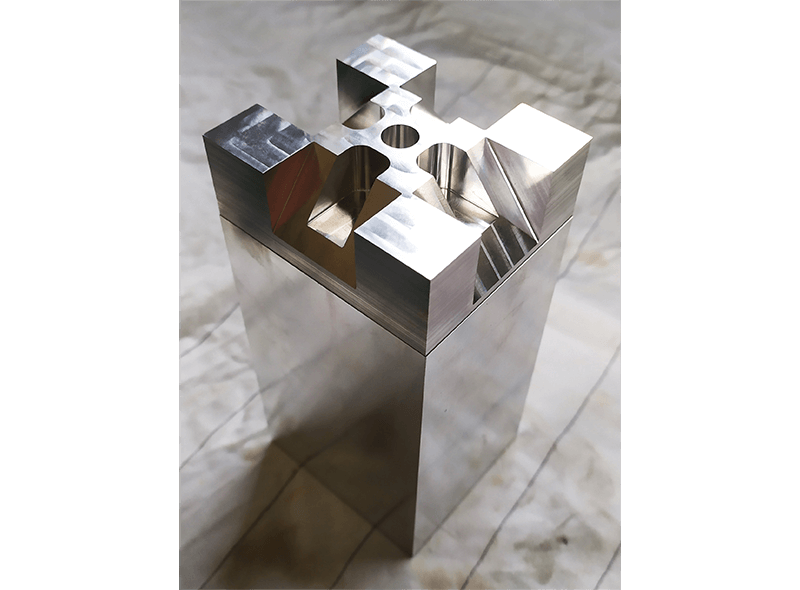

- Material:SKD61-HRC54

- Spindle Speed:13000 rpm

- Recommend:GT-875-5AX

High-hardness material, the five-axis machine can shorten the tool length, reduce vibration during high-speed cutting, smooth surface, and no quadrant angle.

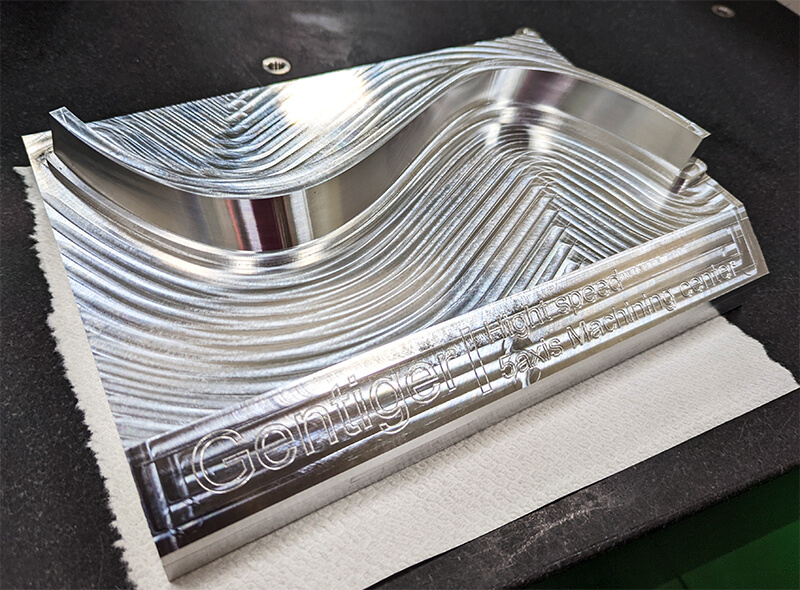

- Material:P20

- Spindle Speed:8000 rpm

- Recommend:GT-875-5AX、GT-HTA2500、GT-H2517F

In the gantry 5-axis high-speed machining center, the swing axis head is positioned and processed at various angles, and the workpiece surface is smooth and without vibration.

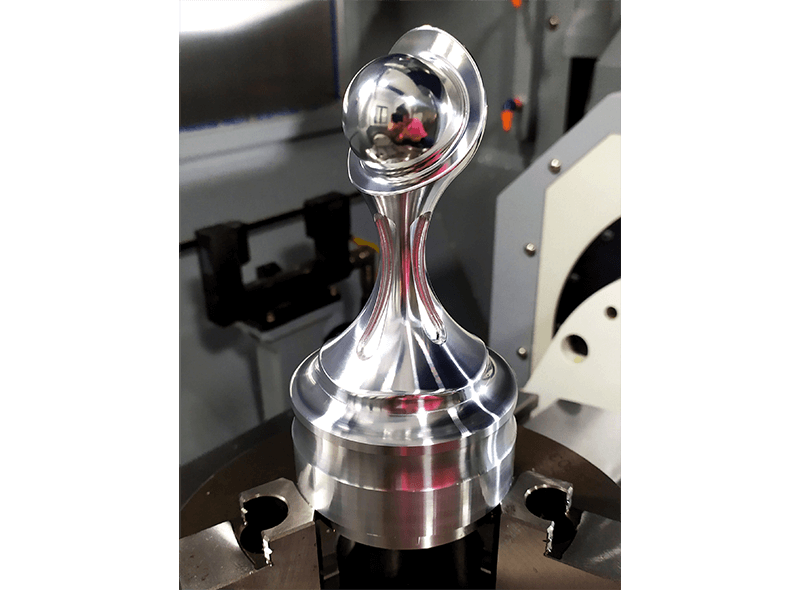

- Material:6061-T6

- Spindle Speed:13000 rpm

- Recommend:GT-875-5AX

Large-angle five-axis simultaneous arc cutting, five-axis simultaneous adjustment, no quadrant angle, and using five-axis machining to reduce the machining of the static point of the tooltip, the surface is smooth, and there is no pick mark for long-term finishing.

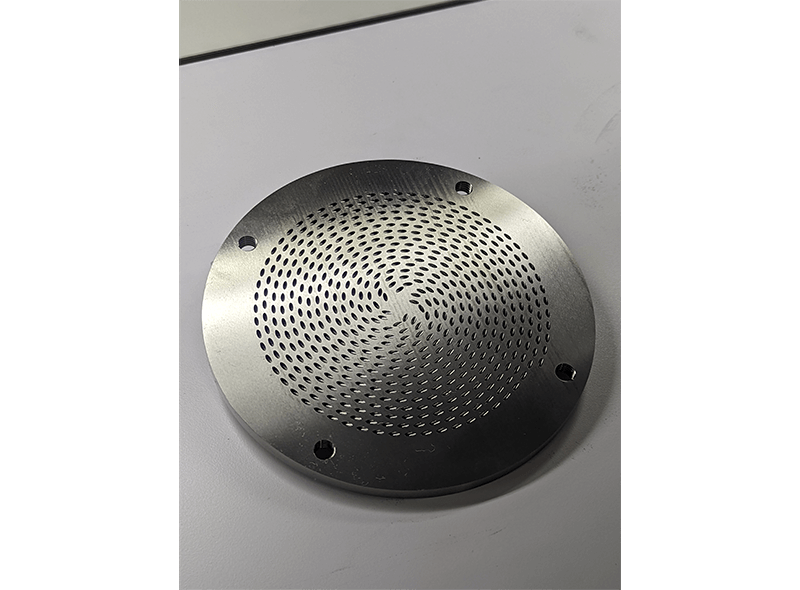

- Material:SUS316

- Spindle Speed:1800 rpm

- Recommend:GT-875-5AX

Thin plate drilling processing, 2250 holes, 65-degree inclination angle, and the long-term drilling positioning accuracy is within 0.01mm.

- Material:6061-T6

- Spindle Speed:5000 rpm

- Recommend:GT-H2517F

The five-axis simultaneous motion of the side wall is used for single-tool processing, with excellent dynamic accuracy, no chattering and overcutting on the surface, and the accuracy is within 0.015mm.